Kamdhenu PAS 10000 Ductility

Safety of concrete structure is of prime concernConcrete is brittle without ductility and cannot be used for structural applications without reinforcement. The ductility within a structure, something which concrete does not have, is provided by steel reinforcement. Therefore, the steel must be sufficiently ductile so that every reinforced concrete section including structural elements, has the capacity to deform by an adequate amount.

Ductility of an element is its ability to withstand deflection or extensive cracking in an overload situation without sudden catastrophic collapse.

Imagine a beam built of plain concrete without reinforcing steel supported at both ends and in the middle. If we load both spans then:

1. On initial loading, the beam deflects a little.

2. In the second stage of loading, the beam collapses all of a sudden.

Now, if the concrete is reinforced with steel bars and loaded in the same way as before then:

1. In initial stage of the loading, the beam deflects a little.

2. In the second stage of loading, the beam continues to deform.

3. In the third stage of loading, the beam deflects some more and small cracks appear.

4. In the fourth stage of loading, the beam deflects even more and cracking becomes more extensive.

In general, higher steel ductility provides greater ductility to the beam.

Bond Strength

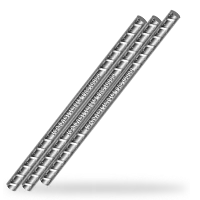

In addition to strength and ductility requirements, reinforced concrete needs adequate bonding between steel and concrete to ensure that the composite works efficiently and cracks are under control. Perfect bonding between concrete and ductility is a property of reinforcing steel that is essential in those applications where structures are subject to unexpected forces (Seismic, dynamic, impact, etc.)

KAMDHENU PAS 10000 boasts more than 200% higher value as compared to basic bond strength as it comes with innovative ribs for ultra strong grip with concrete.

Weldability

KAMDHENU PAS 10000 Bar offers superior weldability than conventional TMT Bars due to its low carbon equivalent. It can be easily butt-welded or lap-welded using ordinary coated electrodes of similar strength. No pre-warming or post-heat treatment is necessary in manual arc welding either.

Corrosion Resistance

While steel is the most durable and strong metal, it is susceptible to basic corrosion that might reduce its life. Corrosion is an electrochemical process that happens with the presence of moisture and oxygen. The iron in the steel gets oxidised to produce rust which occupies and increases upto 6 times in the volume of the original material.

By understanding the science behind corrosion, Kamdhenu PAS 10000, a superior quality of steel has been produced which has a micro-alloy structure and is made with a perfect chemical combination that reduces corrosion. The alloying elements added in the steel, when combined with oxygen, make a thin layer of Alloy Oxide that prevents further rusting and degradation of the steel.

High Temperature Resistance

KAMDHENU PAS 10000 Bar retains more than 80% of its ambient temperature yield strength at 300 °C and 40% at 500 °C.

Degradation of Steel

Degradation of steel is different from corrosion of steel. All kinds of steel form a thin layer of rust on its surface when exposed to air and water. After this thin layer is formed, the degradation process starts which reduces the life of steel. A test named CPR (Corrosion Penetration Rate) was conducted to determine the degradation of steel in milli inch per year.

The results revealed that the degradation of PAS 10000 is 4-6 times less as compared to normal TMT bars thus, increasing the life of steel in a building.

Effective earthquake resistance comes from Strong Floor-slab, Columns and Foundation

Earthquake causes shaking of the ground and as a building rests on the ground, it experiences motion at its base. As per Newton's First Law of Motion, even though the base of the building moves with the ground, the roof has a tendency to stay at its original position. Since the walls and columns are connected to it, they drag the roof along. If the roof has a mass M and experience of acceleration a, the inertia force is mass M times acceleration a, and its direction is opposite to that of acceleration. Larger the mass of building, higher the inertia force and that's why lighter buildings sustain the earthquake more.

Also the Horizontal Inertia forces are transferred from top to foundation through columns, so the connection between Floor-slabs, Columns and Foundation must be strong enough to safely transfer these inertia forces through them.

Seismic Design

Kamdhenu PAS 10000 is best suited for constructions in high seismic zones. When the building structure is subjected to seismic forces; the manner in which the structure reacts is highly dependent on the ductility of the steel and the bond with concrete. Kamdhenu PAS 10000 revealed superior seismic resistance properties during stimulated earthquake conditions.

F=ma is the force that building exerts at the time of earthquake. At the same time, the force at point of contact of steel is F= maSin B1. However, in 360 degree ribs pattern, the same is acting in opposite direction, F=maSin (-B4), i.e., F= -maSin B4 in opposite direction.

The two forces are equal in magnitude but opposite in direction at every point of contact of steel and concrete. Therefore, it reduces the chance of slip of steel from concrete and prevents the building from collapsing at the time of an earthquake and its after-effects.

Wind Load

High rise buildings are subject to heavy wind load. Higher the building, more is the wind load at the top. If stress load crosses beyond the yield stress, it can lead to structural failure. Kamdhenu PAS 10000, being alloy steel has more strength, more load-bearing capacity and more resistant to fracture of steel thus, making high-rise buildings safer.

Kamdhenu PAS 10000 rebars are hot rolled from steel billets & subjected to PLC controlled online thermo mechanical treatment in 3 SUCCESSFUL STAGES

Quenching Stage

Under the Quenching stage, water spray is used as a "Cooling Treatment" to the hot ribbed bars. The effectiveness of the water spraying equipment in this stage is critical as to rapidly harden the surface layer, faster than the critical rate, to form the martensite while core remains austenite.

Tempering Stage

The Tempering stage is very important for bars as after quenching they leave the water quenching line and are exposed to air. The heat flux from the still hot core reheats the surface by conduction thus, self-tempering the surface to a structure called "Tempered Martensite" which is strong and tough. The core is still austenitic at this stage.

Cooling Stage

The third stage of "Atmospheric Cooling" occurs on the cooling bed, where the austenitic core is transformed to a ductile ferrite pearlite core. The final structure consists of a combination of a strong outer layer of tempered martensite and a ductile core of ferrite-pearlite.

Earth-quake resistant DBT3+ Security

Extra Ductility

This deflects beams to reduce load at joints of columns

Extra Strong Bond

The steel bar doesn't slip from concrete and retains its firm grip

Extra Tensile Strength

Higher than normal to reduce fracture of steel

kamdhenu

kamdhenu  kamdhenu

kamdhenu  structural steel

structural steel kamdhenu wirebond

kamdhenu wirebond Kamdhenu

Kamdhenu Color Coated Sheets

Color Coated Sheets Pre-Engineered Buildings

Pre-Engineered Buildings kamdhenu

kamdhenu