Back in the day, constructing a building meant years of patience, a battalion of labour, and the occasional headache when monsoon knocked on your rebar-reinforced dreams. Foundations were dug with sweat, not JCBs, and any talk of “prefab” structures would have earned a raised eyebrow, or worse, a polite dismissal over chai.

But India has come a long way from the blueprint boards of the 1980s. In a world where speed, safety, and sustainability are no longer luxuries but necessities, Pre Engineered Buildings (PEBs) are quietly, yet boldly, reshaping the nation’s construction story. And for those who’ve spent decades working with steel, concrete, and chaos, it’s a transformation worth noticing.

What Is a Pre Engineered Building (PEB) and How Does It Work?

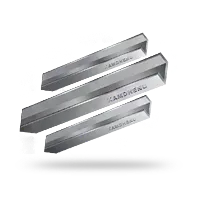

Imagine if a building could be assembled like a well-designed puzzle. That’s essentially what a Pre Engineered Building is: a structural steel framework manufactured off-site and assembled with precision on-site.

Everything, from columns and rafters to wall panels and roofing systems, is engineered in advance using computer-aided design (CAD) software. The components are fabricated in controlled environments, ensuring quality that doesn’t depend on whether the site labourer had his lunch or not.

In technical terms, it’s a modular steel structure that is lighter, faster to erect, and more resource-efficient than traditional construction. But let’s not get too academic here. The real magic lies in its real-world impact.

How Durable Are PEB Structures in Indian Weather Conditions?

Whether you're building in the salt-laden winds of Gujarat, the seismic belts of the North-East, or the blistering heat of Central India, PEBs come equipped to endure.

-

High Tensile Strength: Modern PEB structures, when built with high-quality steel, exhibit excellent strength-to-weight ratios, essential for earthquake-prone zones.

-

Precision Engineering: Controlled factory production means tighter tolerances, fewer defects, and structures that behave exactly as designed, even decades later.

And here’s where Kamdhenu makes its mark. With BIS and ISO-certified steel products that have stood the test of time, Kamdhenu ensures that PEB frameworks don’t just look strong; they are strong. Remember, a house isn’t just a roof over your head. It’s shelter, legacy, and security, especially when built for generations.

Why Are PEBs Faster to Build Than Traditional Structures?

Let’s say you’re overseeing a warehouse build. Under traditional methods, it could take a year (or two, if the local contractor decides to vanish mid-project). But with PEBs, you could be handing over the keys in 4–6 months, thanks to:

In Kamdhenu’s projects, this speed has translated into huge cost savings in some use cases, especially for factories, logistics hubs, and school buildings in rural belts where traditional supply chains can be unreliable.

How Do PEBs Offer Design Flexibility Without Compromising Strength?

You want skylights? Solar panels? Wide-span interiors without obstructive columns? PEBs make all that not just possible but practical.

Their flexible framing system allows for:

Gone are the days when a steel structure meant “ugly but useful.” With modern fabrication, a PEB can be as beautiful as it is brawny.

What Makes Kamdhenu PEBs a Trusted Choice for Durable Infrastructure in India?

When your name is etched into the very fabric of India’s steel landscape, you’re not merely supplying material, you’re enabling dreams to stand tall, from roof to rafter. For over two decades, Kamdhenu has been doing exactly that, cementing its place as one of the country’s most dependable steel brands and now a serious force in the Pre Engineered Buildings (PEB) space.

With a PAN-India presence, more than 80 manufacturing units, and an ISO 9001:2015 certification under its belt, Kamdhenu’s rise in the construction industry isn’t by accident; it’s by precision and persistence.

What Engineering Capabilities Power Quality PEB Manufacturing?

Kamdhenu Build-Tec’s PEB offerings are anything but off-the-shelf. Each project is backed by:

This is not just about supplying steel. It’s about delivering complete PEB solutions, from design and detailing to execution and support.

Which Certifications Ensure the Quality of Pre Engineered Buildings in India?

Kamdhenu doesn’t just promise strength; it proves it. The PEB systems are engineered using the latest design codes and global standards, including:

In short, every nut, bolt, and beam come with the stamp of technical validation; essential when you're building for the long haul.

How Do Technical Teams Support PEB Projects From Start to Finish?

Kamdhenu’s in-house technical teams work closely with contractors, architects, and developers to:

It’s the difference between selling a product and being a project partner. And in an industry where every rupee and reinforcement counts, that difference matters.

Are PEBs the Smart, Future-Ready Solution for Indian Construction?

For the men who’ve built homes brick by brick, monitored every steel binding, and argued over cement ratios with site supervisors, this change might seem like a leap. But it’s a leap worth taking.

Pre Engineered Buildings are not here to replace the soul of Indian construction. They're here to strengthen it. Faster, safer, and smarter; without losing the steel spine that’s built this country.

And when that steel spine is Kamdhenu-certified, tested, and trusted, you’re not just building fast. You’re building right.

kamdhenu

kamdhenu  kamdhenu

kamdhenu  structural steel

structural steel kamdhenu wirebond

kamdhenu wirebond Kamdhenu

Kamdhenu Color Coated Sheets

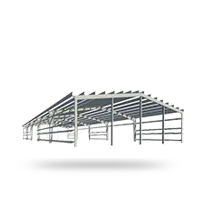

Color Coated Sheets Pre-Engineered Buildings

Pre-Engineered Buildings kamdhenu

kamdhenu