There is an unheard shift in the construction of warehouses, factories, farm sheds, infrastructural assets, and other commercial spaces in India. Changes are being made towards accelerating faster, simpler, and highly durable construction methods as opposed to the more traditional approach of brick-and-mortar. One such innovation is Pre Engineered Steel Buildings (PESBs) which have shown to be useful across various industries.

There is more to this shift than simply trend spotting. It’s an outcome-enabled response in the real world when it comes to addressing challenges like speed of construction, structural reliability, and cost considerations. For middle-aged consumers who have experienced decades of industrial growth in India, coming to terms with this new construction method is important as is viewing it not only as an advantage in construction materials but an evolution of the Indian steel industry in catering to future needs.

What Are Pre Engineered Steel Buildings?

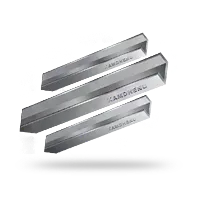

Pre Engineered Steel Buildings are unlike conventional buildings where steel frames, secondary members, roofing sheets, fasteners, and insulation systems are designed and prefabricated off-site rather than constructed on-site. These components are assembled to form primary PESB structures and transported to construction sites which lets assembly be done more efficiently.

Due to the modular approach, construction time is cut down, the amount of labour needed on-site is decreased, and material waste is lowered - making it useful for industrial, agricultural, and even semi-commercial purposes.

Why are Pre Engineered steel buildings trending in India?

India’s economic and industrial developments are booming at a very fast pace in rural and semi-urban areas. Here speed, durability, and cost are three priorities. There is growing attention to this market from Pre Engineered Building Suppliers who now sell custom designs that are corrosion protected, seismic resistant, and compliant with national safety, steel, and engineering standards.

Some key advantages are provided below:

- Shorter Turnaround Time: PESBs can be completed in weeks instead of months which is crucial for companies that do not want extensive delays to their projects.

- Cost Effective: These buildings become more economical over time because they require less labour, material, and maintenance, and have lower upkeep.

- Environmental Impact: These buildings use steel which is 100% recyclable, and the carbon footprint is significantly reduced with off-site fabrication.

- Design tailorability: PESBs can be designed for specific needs such as warehouses, poultry sheds, and storage units.

Uses Other Than Industrial Building Customs

One of the most common misconceptions of Pre Engineered Steel Buildings is that they only include the construction of factories and godowns. This is not the case as their uses include but are not limited to the:

- Cold Storage Facilities: These are pivotal for India’s developing AgriTech and food logistics verticals.

- Private Schools and Colleges with Their Auditoriums: Schools can complete sooner, allowing faster project rollouts, which is perfect for P3 projects.

- Motor Vehicle Showrooms and Service Stations: Where open floor plan designs along with high visibility are very essential.

- Agricultural Infrastructure: Such as grain storage units and farm equipment sheds, which steel’s weatherproof, corrosion resistant, durable, and long-lasting.

An Evolution That is Under the Radar/index of Steels in India

With so many other players coming into this space, few have taken the step lead in focusing on engineering-grade PESB systems. For instance, Kamdhenu has started to produce solutions for Pre Engineered buildings with design precision and structural integrity, which is a step forward in the narrative of construction in India. These modular, multi-use systems are tailored for a variety of terrains and mark ingenuity in Indian construction systems.

Even without any special efforts to market it, these innovations are changing the infrastructure in both small towns and industrial areas. For someone familiar with the Indian steel sector, this marks a comeback to performance-centred value engineering, where ‘how well’ overpowers ‘how it looks’.

Final Thoughts: Transforming Infrastructure

A new era of construction is at India's doorstep: one where steel is synonymous with efficiency, durability, and sustainability. Pre Engineered Steel Buildings are an intelligent answer to modern infrastructural needs, especially in regions where speed and cost efficiency are critical.

There is little doubt this will change with more Pre Engineered Building Suppliers innovating these systems to support everything from logistics hubs to farm infrastructures. Observers of India's industrial and construction sectors agree: the evolution will not happen brick by brick, but rather beam by beam - precision-crafted, pre-assembled, and ready to rise.

kamdhenu

kamdhenu  kamdhenu

kamdhenu  structural steel

structural steel kamdhenu wirebond

kamdhenu wirebond Kamdhenu

Kamdhenu Color Coated Sheets

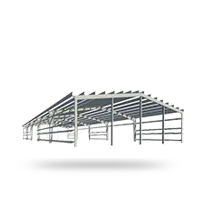

Color Coated Sheets Pre-Engineered Buildings

Pre-Engineered Buildings kamdhenu

kamdhenu