- About us

- Our brands

- Partner program

- Investor Zone

- Credit Rating

- Financial Results

- Annual Report

- Annual Return

- Shareholding Pattern

- Investor Information

- Notice to Shareholders

- Presentation/ Press Release/ Transcript

- Media Coverage

- Code of Conduct & Policies

- Stock Exchange Disclosures

- Subsidiary Financials

- scheme of arrangement

- Investor Help Desk

- General Meeting

- Disclosures under Regulation 46 of the LODR

- Disclosure under Regulation 30 of LODR

- Quick Links

- About us

- our brands

kamdhenu

kamdhenu

NxtProduced in a state-of-the-art

Read More...

kamdhenu

kamdhenu

PAS 10000Kamdhenu, one among

Read More...

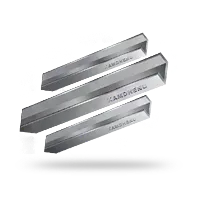

structural steel

structural steelThe product has high strength,

Read More...

kamdhenu wirebond

kamdhenu wirebondManufactured with ultra

Read More...

Kamdhenu

Kamdhenu

PipesGrowing with its diversification..

Read More...

Color Coated Sheets

Color Coated SheetsDiscover the world of colours..

Read More...

Pre-Engineered Buildings

Pre-Engineered BuildingsKamdhenu PEB system is..

Read More...

kamdhenu

kamdhenu

paintsGrowing with its diversification..

Read More...

- partner program

- Business Partners

Kamdhenu Limited. has been a pioneer in this revolutionary concept of Franchisee Model having attained success in the middle tier steel segment on a regional front.

Read More...

- Kamdhenu Edge

Kamdhenu Group is the first company to introduce Branded steel products in India. We have integrated with independent producers through efficacious Franchisee Association Business Model..

Read More...

- Partner Stories

With multiple levels of support available from the corporate office for an experienced business owner or a first-time franchise partner. You will have access to many resources that will help you grow your business.

Read More...

- Business Partners

- Investor Zone

- Credit Rating

- Financial Results

- Annual Report

- Annual Return

- Shareholding Pattern

- Investor Information

- Notice to Shareholders

- Presentation / Press Release/ Transcript

- Media Coverage

- Code of Conduct & Policies

- Stock Exchange Disclosures

- Subsidiary Financials

- scheme of arrangement

- Investor Help Desk

- General Meeting

- Disclosures under Regulation 46 of the LODR

- Disclosure under Regulation 30 of LODR