December 30 2025

December 30 2025

The Versatility of Square Hollow Section (SHS) Pipes in Modern Architecture and Fabrication

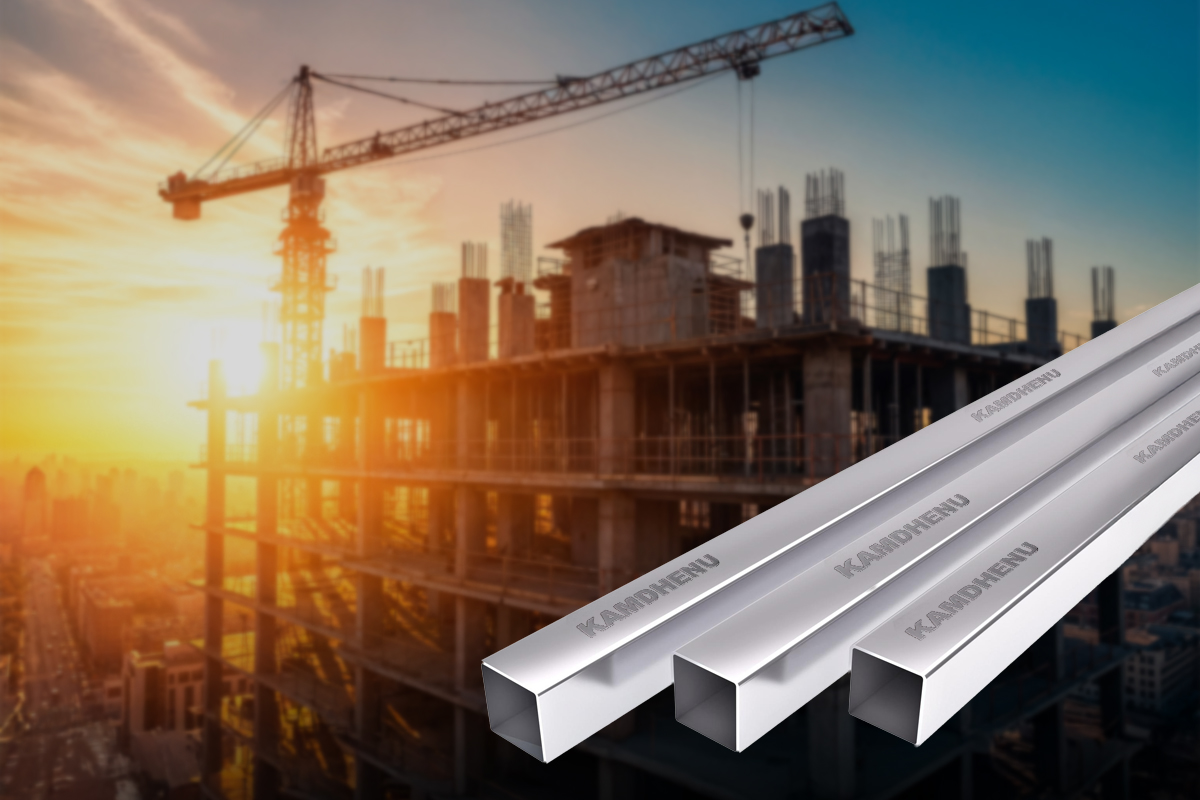

Modern buildings aim to look clean and stylish, while staying strong and affordable. One quiet hero behind this is the Square Hollow Section steel member. You will see it in façades, frames, railings, gates, canopies, and even designer furniture. In India, fabricators often call it an MS Hollow Square Pipe. This blog explains where SHS works best, why architects like it, and what to check when you buy, in simple language.

What is a Square Hollow Section?

A Square Hollow Section is a steel section with a hollow square cross-section. Think of it as a steel box with equal sides.

Key points in simple words:

- Equal sides give balance in both directions.

- Hollow core reduces weight compared to solid bars.

- Flat faces make fabrication and cladding easier.

When made from mild steel, we commonly call it an MS Hollow Square Pipe. It is rolled and welded from strip, then sized to exact dimensions.

Why architects prefer SHS in modern design

Architects like clean lines. SHS helps them achieve that.

Main reasons:

- Flat surfaces and sharp edges look neat in façades and frames.

- Sections can be kept slender but still strong enough for the span.

- Joints look cleaner compared to angles and channels.

In glass façades, pergolas, and boundary designs, SHS helps balance strength with a simple, modern look.

Structural advantages in frames and sheds

For frames, SHS gives good strength in both directions. This is useful for columns, portal frames, and trusses.

Benefits for structural use:

- High strength-to-weight ratio.

- Better torsion (twist) resistance than many open sections.

- Good performance as columns and as members in rectangular frames.

In small industrial sheds and commercial canopies, an MS Hollow Square Pipe frame often feels more rigid and looks more refined than one made only with angles.

Where Square Hollow Section is used in architecture and fabrication

Some common applications in India:

- Façade frames for glass and ACP panels.

- Balcony and staircase railings with a minimalist look.

- Entrance gates, grills, and boundary frames.

- Signage structures and hoardings.

- Canopies, pergolas, and sunshade frames.

- Mezzanine and light platform frames, when properly designed.

- Furniture, kiosks, and shop interiors.

Because SHS is easy to cut and weld, fabricators can use it in both heavy and light work.

Square Hollow Section vs other steel sections

When you choose sections, it helps to compare.

| Use case | Square Hollow Section | Angles / Channels |

|---|---|---|

| Aesthetic frames | Very clean, modern look | More industrial, visible flanges |

| Torsion resistance | Better for twisting loads | Weaker in torsion for same weight |

| Cladding and glazing | Flat faces support panels well | Needs more sub-members to fix panels |

| Railings and gates | Neat lines, fewer dust traps | More corners and edges for dust |

| Weight for stiffness | Good balance | Depends strongly on orientation |

This is why many modern architects specify Square Hollow Section for visible work and use channels or I-beams where the structure is hidden.

How to select the right SHS size and thickness

Choosing an MS Hollow Square Pipe is not just about what “looks right”. It should be sized for strength and service.

Guidelines:

For columns and main frames:

Pick larger sections with thicker walls for load-bearing work.

For rafters and secondary members:

Mid-size sections may be enough, as per the structural design.

For railings, grills, and light frames:

Smaller sizes with suitable thickness provide stability without looking bulky.

Always follow the structural engineer’s design for load-bearing members. Do not reduce wall thickness only to save cost.

What to check when you buy a Square Hollow Section

Simple checks at delivery help you avoid trouble later:

- Size and wall thickness: Measure the outer size and wall thickness on random pieces.

- Straightness: Sight along the length; there should be no big bow or twist.

- Squareness: Check corners; all four sides should be equal, faces flat.

- Weld seam: Seam should be smooth, without undercut or burn-through.

- Surface: No deep rust pits or scale; light rust can be cleaned before priming.

These checks are simple but very important for neat fabrication and long-term strength.

Read More: The Rise of Rectangular Hollow Sections in Indian Construction

Money matters: cost vs overall value

An MS Hollow Square Pipe from a reliable brand may cost a little more per kilo than low-end options. But total value often works out better.

You save money in:

- Less rework due to accurate sizes and straightness.

- Faster fit-up and welding with true corners.

- Reduced grinding and filling at joints.

- Better paint finish, which slows corrosion and repainting.

For large frames and high-visibility work, this difference becomes clear as the project progresses.

Why consider Kamdhenu for SHS needs

Kamdhenu is known in the Indian market for structural products and a strong dealer network. For Square Hollow Section and other structural items, this helps you in three ways:

- Access to standard sizes that designers and fabricators know well.

- Consistent quality, so members behave the same across batches.

- Easier documentation and support if you need clarifications or test details.

If your project uses Kamdhenu for other steel items or roofing, using Kamdhenu SHS also keeps coordination and record-keeping simple.

Practical tips for fabrication and safety

To get the best from SHS:

- Use proper cutting tools and keep blades sharp to avoid hard burns.

- Deburr cut edges; this helps both safety and paint finish.

- Drill with correct speeds and bits for cleaner holes.

- Prime soon after fabrication, especially in humid or coastal areas.

- Provide drain holes in closed frames so water does not collect inside.

In safety terms, lift bundles with slings, not chains, directly. Store sections off the ground on sleepers, and keep them covered from direct rain where possible.

FAQs about Square Hollow Section in India

Q1. Is a Square Hollow Section only for light work?

No. With the correct size and thickness, SHS can be used for serious structural work as per design.

Q2. Can SHS replace I-beams everywhere?

Not everywhere. I-beams are still better for many heavy beams. SHS is excellent for columns, frames, and architectural members when designed properly.

Q3. Is SHS more expensive than angles?

Per kilo, sometimes similar, sometimes a bit higher. But for the same stiffness and look, SHS can reduce member count and finishing time.

Q4. Can SHS be used outdoors?

Yes. Use proper primer and paint, or galvanising for harsh / coastal conditions.

Conclusion

The Square Hollow Section has become a favourite in modern Indian architecture and fabrication because it blends strength, neat looks, and practical handling. An MS Hollow Square Pipe gives clean lines for façades and gates, strong frames for sheds and canopies, and flexible options for interiors and furniture.

When you plan a project, think beyond just “angle and channel”. Talk to your engineer and fabricator about SHS where it makes sense. Choose a dependable brand like Kamdhenu for consistent quality, available sizes, and easier support. With the right section, thickness, and protection, your frames will stay straight, look elegant, and serve you well for many years.