December 01 2025

December 01 2025

The Definitive Guide to Choosing the Best TMT Bar for House Construction

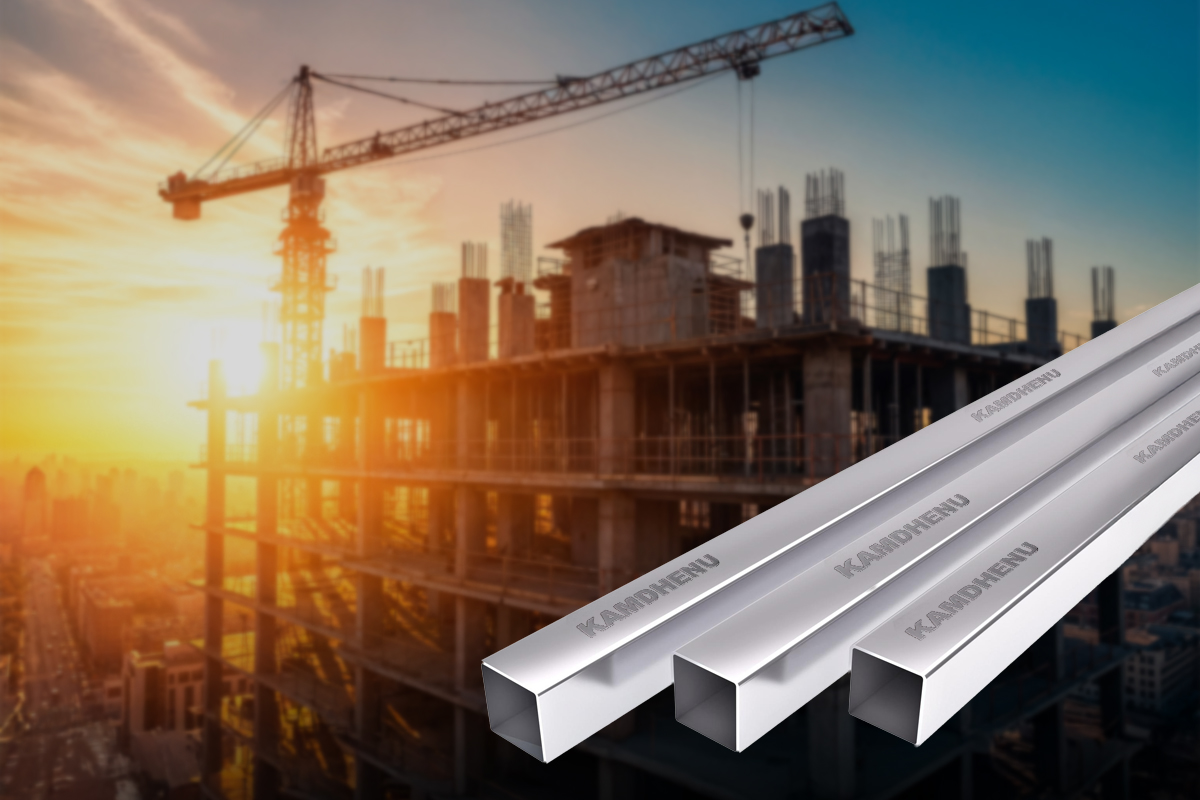

Concrete is strong in compression but weak in tension. TMT Saria (TMT bars) handle the pulling and pushing forces. If the bar is weak, brittle, or undersized, cracks form early, and safety declines. If the bar is strong and ductile, your house can better handle loads, heat, and even tremors.

The goal is simple. You want steel that’s flexible when needed, does not snap suddenly, and is the right grade for your area. Kamdhenu is often chosen for this reason, because it focuses on consistent quality and easy availability through dealers.

Understanding TMT grades for house construction

When people ask about the Best TMT Bar for House Construction, the first thing to understand is grade. You will usually hear names like Fe 500/550 or Fe 500D/550D.

-

Fe 500/550: Fe means iron. The number 500/550 is the minimum yield stress in MPa. A higher number means higher strength.

-

D in Fe 500D/550D: D means more ductility. Ductility is the ability to bend and deform without breaking.

For most Indian homes:

-

Fe 500/550 is a safe, common choice.

-

Fe 500D/550D is better in earthquake‑prone zones or where you want extra safety.

Think of it like this. Fe 500D/550D gives a bit more “give” before failure. That helps during tremors.

How to decide the right grade for your house

You should never pick a grade only by price. Look at three things.

Location of your plot

- Seismic or earthquake zone: Prefer Fe 500D/550D or another high‑ductility grade.

- Low risk area: Fe 500/550 can be enough, as per the engineer's design.

Type of structure

- G+1 or G+2 home: Fe 500/550 or Fe 500D/550D as per design.

- Heavier or more complex house: Ductile grade is usually better.

Future plans

- If you may add floors later, tell your engineer now. They can pick the grade and diameter mix accordingly.

Your structural engineer’s design must be followed. Do not change the grade on site without written approval.

What to look for in TMT Saria on-site

Even if you select the right grade, poor-quality bars can harm the structure. When bundles reach the site, do a quick check.

-

Ribs should be deep, even, and continuous along the bar.

-

Bar should be straight, without sharp bends or twists.

-

There should be no deep rust pits or flaking. Light brown rust is usually fine.

-

Brand name, size, and grade should be clearly marked on the bar at intervals.

If any bundle looks very different from the rest in colour, rib pattern, or marking, keep it aside and ask your supplier.

Documents you should always ask for

Good brands make this part simple. Before cutting and bending, ask your dealer for:

-

Mill Test Certificate (MTC) for each batch.

It shows chemical composition and mechanical properties like yield strength, tensile strength, and elongation.

Keep a copy of these documents in your house file. This is useful if any question comes up later.

How to compare brands beyond just price

When you search for the Best TMT Bar for House Construction, you will see many brand names. Here is a simple comparison logic.

|

Factor |

What you should check |

Why it matters for your house |

|

Grade options |

Fe 500/550, Fe 500D/550D, higher ductility variants |

Lets your engineer choose the safe option |

|

Markings |

Clear brand, size, grade on bar |

Helps avoid mix‑ups on site |

|

Certificates |

Easy access to MTCs and test data |

Builds trust and proof for quality |

|

Dealer network |

Nearby stockist with regular supply |

Reduces delays and last‑minute brand mixing |

|

Consistency |

Same behaviour from bundle to bundle |

Bending and fixing become predictable |

Kamdhenu usually scores well on these points, which is why many engineers and contractors keep it in their shortlist.

Money matters: rate vs total cost.

Most owners ask first, “What is today’s rate per kg?” That is natural. But the steel cost has two parts.

-

Direct steel price

The rate per kg that you pay for TMT Saria.

-

Indirect cost

Extra labour if bending is hard.

Wastage if bars crack at bends.

Delays if the stock is not available on time.

Repair and strengthening costs later if cheap steel fails.

A slightly lower rate from an unknown source can become expensive in the long run. A steady brand like Kamdhenu may look a bit higher some days, but it usually saves money through less wastage and smoother work.

Simple on‑site tests for peace of mind

These are basic checks you can ask your contractor to do on small sample pieces.

-

Bend test: Take a short length. Bend it to the required angle, with proper mandrel dia. A good bar will not show surface cracks or breaks.

-

Diameter and weight check: Measure the diameter with a vernier. Weigh a known length and compare with standard tables. This confirms that you are truly getting the size you paid for.

-

Rib impression test: Press a bit of wet cement paste on the ribs and remove it. Sharp, clear rib marks suggest a better grip with concrete.

Do not try to do heavy mechanical tests on site. Those belong in labs. But these small checks give useful signals.

What to check at delivery for every truck

When a new lot of TMT Saria arrives, run through this quick list:

-

Does the invoice clearly mention brand, size, grade, and quantity?

-

Are the bars stored off the ground, on wooden sleepers?

-

Are the different sizes properly separated to avoid mix‑up?

Choosing the Best TMT Bar for House Construction: Quick Steps

You can follow this 7‑step path:

-

Discuss with your structural engineer about the grade and size mix.

-

Shortlist 2–3 known brands, including Kamdhenu.

-

Check who can give Fe 500D/550D or other ductile grades if you are in a seismic zone.

-

Confirm that the dealer can supply the full required quantity in the same brand.

-

Ask in advance for Mill Test Certificates for each lot.

-

Inspect the first delivery carefully and do a small bend test.

-

Stick to the same brand and grade for each structural element.

This way, your decision is guided by safety and consistency, not just by rate.

FAQs about TMT Saria for home builders

Q1. Which grade is best for a normal house?

For most houses, Fe 500/550 is common. In earthquake‑prone areas, Fe 500D/550D or a higher ductility grade is better. Always follow your engineer.

Q2. Can I mix brands in one slab or beam?

Better to avoid. Mixing brands and grades within the same member can change behaviour. Use one brand and one grade per element.

Q3. Is a higher grade always better?

Not always. Higher grade must match the design. Very high strength with poor ductility is not good for homes in seismic zones.

Q4. Why do prices change so often?

Steel follows raw material and market movement. That is normal. The key is to compare like‑for‑like on the same day.

Conclusion

The Best TMT Bar for House Construction is not only about a big name or the lowest rate. It is about the right grade, reliable ductility, honest diameter, and steady supply. Good TMT Saria will bend without cracking, grip concrete well, and stand strong for decades.

Work with your engineer, choose a trusted brand like Kamdhenu, ask for test certificates, and do simple on‑site checks. If you follow these steps calmly, your home will have a strong backbone that quietly protects your family through heat, rain, and tremors.