December 29 2025

December 29 2025

Pre-Engineered Buildings (PEB): Revolutionising Warehouse and Industrial Construction in India

Warehouse and factory projects in India now run on tight timelines and tight margins. Delays hurt business. Heavy on-site welding raises risk and cost. This is where Pre-engineered buildings have changed the game. Steel frames and sheeting are designed and manufactured in a factory, then quickly bolted together at the site.

This blog explains how PEBs are reshaping warehouse and industrial construction, what to check when you talk to PEB Structure Manufacturers, and how a brand like Kamdhenu fits into the picture.

What are Pre-Engineered Buildings in simple words?

Think of Pre-Engineered Buildings as a ready design and supply package for steel sheds and industrial halls. The main parts are:

- Steel frames designed for your span, height, wind, and seismic data.

- Purlins and girts that carry the roof and wall sheets.

- Roof and wall cladding, usually colour-coated steel sheets.

- Bolts, brackets, and accessories that tie everything together.

Most cutting, drilling, and welding is done in the factory. At the site, the job is mainly lifting parts into place and tightening bolts.

Why PEBs are ideal for warehouses and industrial sheds

For warehouses, logistics hubs, and plants, speed and clear space are critical. PEBs help here.

Key advantages:

- Fast construction: While foundations are being cast, frames and sheets are made in the factory.

- Large clear spans: You can have fewer columns and more usable floor space for racking and machines.

- Predictable quality: Members are made under factory control, so sizes and holes are consistent.

- Easier expansion: You can add bays in future if demand grows.

A well-designed PEB can often be commissioned weeks earlier than a conventional shed.

Main benefits of Pre-Engineered Buildings for Indian projects

Let us break down the benefits that matter to Indian owners and contractors.

Speed of delivery and erection

- Parallel activities reduce overall project time.

- Less hot work on site means faster erection and fewer stoppages in bad weather.

Cost control over the project life

- Optimised steel weight reduces overall tonnage.

- Factory cutting minimises scrap and site waste.

- Good sheeting and drainage lower maintenance and leak repair costs.

Operational flexibility

- Wide bays and high clear heights suit pallet racking, conveyors, and cranes.

- Mezzanines, canopies, and office blocks can be integrated into the same frame system.

Safety and quality

- Less on-site welding reduces fire and injury risks.

- Documented design and material traceability support approvals and insurance.

How PEB Structure Manufacturers Add Value

Not all PEB suppliers are the same. When you speak with PEB Structure Manufacturers, see how they manage these points:

- Engineering: Use of proper Indian codes for wind and seismic design. Clear connection details.

- Detailing: Clean shop drawings, clear mark numbers, and logical erection sequence.

- Fabrication: Proper welding, cutting, and hole drilling practices with checks in place.

- Cladding: Use of coated steel sheets with known thickness and coating class.

- Support: On-site supervision or guidance during critical erection stages.

A strong PEB partner will share drawings and material lists in a way your engineer and contractor can understand and verify.

Read More: Pre-Engineered Steel Buildings vs. Conventional Construction: Which One Wins?

Comparing PEB vs conventional steel sheds

| Aspect | Pre Engineered Buildings | Conventional steel / RCC shed |

|---|---|---|

| Design and detailing | Integrated package from one source | Often split across designer and fabricator |

| Construction speed | Higher, due to factory work and bolt erection | Lower, more on-site fabrication and curing |

| Quality control | Better, factory tolerances and standard parts | Depends heavily on site team |

| Changes and expansion | Easier to add bays later | Harder, often needs re-design |

| Site labour and hot work | Lower welding, more bolting | More hot work at height |

For most modern warehouses and industrial sheds, PEBs win on speed, predictability, and value over time.

What to check before finalising a PEB proposal

Since this is product-focused, let us look at what you should ask before you sign.

Scope clarity

Confirm what is included: main frames, secondary members, sheeting, flashing, gutters, downpipes, fasteners, and erection support.

Steel and sheet specifications

Ask for grades, estimated steel weight, and the base metal thickness and coating of the roof and wall sheets.

Loads and design basis

Share your location, wind and seismic zone, crane loads, mezzanine loads, and any special equipment loads. Make sure these are clearly mentioned in the proposal.

Erection plan

Ask for a broad schedule: number of days for structure, sheeting, and finishing, with an indicative crew size and crane capacity.

Documents and tests

Check that Mill Test Certificates and basic QA records will be provided for structural members and sheets.

How Kamdhenu connects with PEB projects

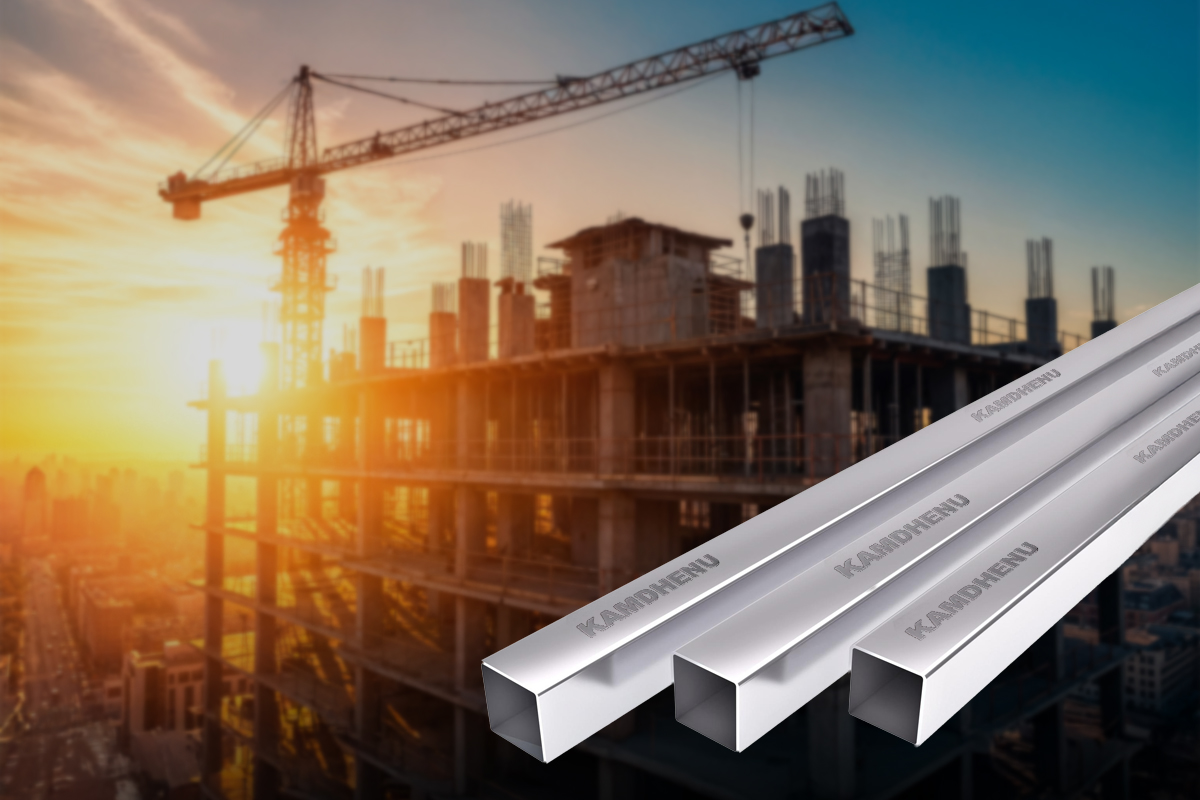

Kamdhenu is well known for steel products such as TMT, structural sections, and roofing sheets in India. While specialist PEB Structure Manufacturers design and fabricate the frames, they still need reliable steel and cladding.

Kamdhenu can support PEB projects by:

- Supplying consistent coated roofing and cladding sheets.

- Providing structural products like beams, channels, and hollow sections that integrate well into PEB designs.

- Backing this with a wide dealer network, which helps with quick top-ups, repairs, and future extensions.

So when a PEB vendor and Kamdhenu products work together, you get a smoother project from design to maintenance.

Money matters: looking beyond “rate per square foot”

Many buyers ask only, “What is the cost per square foot?” That is a start, but not enough.

Also look at:

- Total steel weight and grade for the structure.

- Thickness, coating, and paint of the sheets.

- Inclusion of gutters, downpipes, louvres, and skylights.

- The extent of erection and supervision included in the price.

- Long-term cost of leaks, repainting, and future expansion.

Sometimes, a slightly higher initial quote from a serious PEB supplier with better materials and support works out cheaper over the building's life.

Practical tips for a smooth PEB project

Here are a few simple habits that reduce stress later:

- Freeze building layout, bay spacing, and clear height as early as possible.

- Decide on openings for loading bays, doors, and windows before final approval of drawings.

- Plan for ventilation and natural light (vents and skylights) to reduce future energy costs.

- Ensure anchor bolts are cast accurately using the templates provided.

- Keep an organised yard for unloading and storing members to avoid damage and confusion.

Good planning from your side allows the PEB partner to deliver their best.

FAQs about Pre-Engineered Buildings in India

Q1. Are PEBs strong enough for heavy industrial use?

Yes, if designed with correct loads and codes. Many factories, warehouses, and logistics hubs now use PEBs safely.

Q2. Do PEB roofs leak more?

Not if slope, overlaps, fasteners, and gutters are designed well and installation follows the method. Leaks usually come from poor detailing or careless fixing.

Q3. Can you extend the PEB later?

Yes. You can usually add bays at the gable side if the new design matches the old.

Q4. Are PEBs only for large projects?

No. They also work well for medium warehouses, showrooms, workshops, and even some institutional buildings.

Conclusion

Pre-Engineered Buildings have changed how India builds warehouses and industrial sheds. They combine speed, clean spans, and factory-level quality with the flexibility to expand in future. A good PEB solution is not just about a sheet on paper. It is about well engineered frames, reliable sheets, honest specifications, and a clear erection plan.

While assessing PEB Structure Manufacturers, figure out design clarity, material quality, documents, and support, apart from the rate per square foot.

By offering a variety of steel and roofing products and having an efficient distribution network, Kamdhenu is a perfect fit for this ecosystem as a reliable material partner.

With a suitable PEB partner and reliable materials, it is possible that your next storage or industrial building will be able to be built in a short time, function efficiently, and have a low maintenance cost throughout its lifespan.