December 01 2025

December 01 2025

TMT Bar Price Analysis: What Determines the Cost of Quality Steel in India Today?

TMT is one of the biggest cost heads in any building today. When the TMT Bar Price moves even by a small amount, the total budget changes a lot. Many buyers ask, “Why is steel so expensive?” and “What am I really paying for?” This guide explains the main factors behind the price of a TMT Steel Bar in India in simple, practical language.

Why understanding TMT Bar Price matters?

When you understand what drives price, you can make better decisions. You stop chasing the lowest rate and start looking for true value. For a house or small project, the aim is simple. You want safe steel, steady quality, and fair pricing. Knowing the logic behind TMT Bar Price helps you talk confidently with dealers and plan your cash flow better.

Raw material costs: where the price journey starts

Every TMT Steel Bar begins as iron ore, coal, or other energy sources, and recyclable steel. When the cost of these inputs goes up, mills cannot avoid increasing prices.

- Iron ore and pellets: If ore prices rise, sponge iron and billets become costlier.

- Energy and fuel: Power, gas, and coal costs affect furnace and rolling expenses.

- Recyclable steel: Many mini mills depend on recyclable steel. Recyclable steel price swings reflect global demand.

These costs move daily or weekly. That is why you often see the TMT Bar Price changing almost every day in dealer markets.

Manufacturing route and technology

Not all TMT comes from the same type of plant. Production route affects both quality and cost.

- Integrated steel plants: They control the full chain from ore to finished bar.

- Secondary or mini mills: They melt recyclable steel or sponge iron in furnaces for making billets and roll it.

Modern mills with better automation and quenching systems may have slightly higher setup costs. But they deliver more consistent TMT Steel Bar properties and fewer defects. This consistency reduces wastage and rework on-site. So, even if the tag price is a bit higher, the total project cost may be lower.

Grade and ductility: Fe 500/550 vs Fe 500D/550D and beyond

Higher grade and higher ductility are not “free upgrades”. They need stricter chemistry and tighter process control.

- Higher strength (like Fe 500/550): Needs proper alloying and rolling control.

- Higher ductility (D grade): Needs careful cooling control and better base steel.

So, a Fe 500D/550D bar can be slightly costlier than a basic lower-grade bar. But it offers better performance in seismic zones and at high loads. For a home, this can mean fewer cracks and better safety in an earthquake.

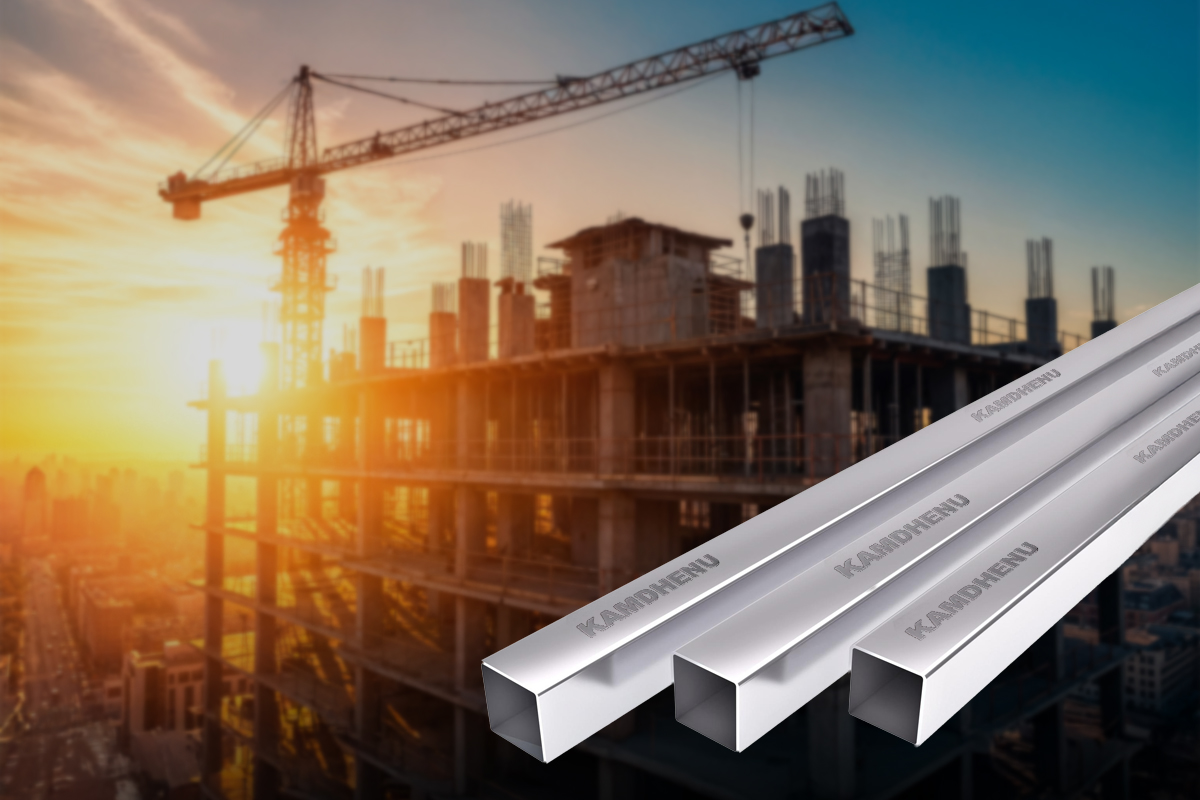

Size, weight, and brand honesty

Two brands may quote different TMT Bar Price per ton, but the real question is: are you getting full size and full weight?

- True diameter: An 8 mm bar must actually measure more than 8mm in ovality.

- Weight per meter: This must match standard tables closely.

Some low-price options quietly cut size or weight. At first, the rate looks attractive. But you are actually getting less steel for the same money. A trusted brand like Kamdhenu focuses on actual section weight and consistent diameters. So you pay a fair price for full material.

Quality control and testing

There is a cost to proper testing, but it protects you.

Serious mills will spend on:

- Lab equipment and trained staff.

- Regular sampling for yield, tensile strength, and elongation.

- Bend and re-bend tests to confirm ductility.

- Chemical checks to keep harmful elements lower than the range given in IS standard.

This adds to the total cost per ton. But it cuts the risk of brittle bars, surprise failures, and site problems. When you pay a little extra for a proper TMT Steel Bar, you are also paying for this hidden safety net.

Freight, handling, and distance to site

Transport is a real part of the TMT Bar Price in India, especially for remote projects.

Key points:

- Distance from the mill or stockyard to your site.

- Mode of transport and fuel prices.

- Load size: Full-truck loads work out cheaper per ton than small lots.

Often, you will see that the same brand has a different price in two nearby towns. Freight, local unloading costs, and dealer margins can explain this.

Demand, supply, and season

Market forces also move the TMT Bar Price up and down.

- Construction season: Pre-monsoon and post-monsoon periods often see higher demand.

- Government projects: Big infra orders can tighten supply, especially in some regions.

- Global steel cycle: Export demand, import duties, and global prices also play a part.

For a house builder, this means it is good to track prices for some weeks before placing a large order. But do not wait forever for the “lowest” day. The more important thing is to lock a stable brand and grade.

Price vs value: how to compare offers

Here is a simple way to compare two offers.

| Checkpoint | Offer A | Offer B |

|---|---|---|

| Brand and grade | Known brand, Fe 500D/550D | Unknown brand, Fe 500/550 |

| Actual size | Full size confirmed | Not clearly mentioned |

| Documents | Mill Test Certificates available | No MTC promised |

| Dealer support | Nearby dealer, regular stock | Small trader, uncertain supply |

| Rate per ton | Slightly higher | Lower |

Even if Offer A has a bit higher TMT Bar Price, in many cases it is the better choice. Reason: you get reliable quality, documents, and a steady supply. That usually means fewer delays, less wastage, and better safety.

How Kamdhenu fits into this picture

Kamdhenu works in the branded segment. The focus is on:

- Consistent grade and ductility, suitable for a wide range of Indian conditions.

- Clear marking on the TMT Steel Bar for identification.

- Support through a dealer network, so you can get test certificates and clarifications easily.

So, while day-to-day TMT Bar Price may move with the market, the quality, size, and service stay steady. Many engineers and contractors like this balance.

Practical tips to manage TMT cost on your project

You cannot control the market, but you can control decisions at your end.

- Finalise the steel grade and quantity early with your structural engineer.

- Track the TMT Bar Price for a couple of weeks to understand the range.

- Buy in logical lots instead of many tiny deliveries.

- Store bars off the ground and covered, to avoid rust and wastage.

- Do not change brand or grade in the middle of a slab or beam just to save a little.

These small habits often save more than chasing a last-minute one-rupee discount.

FAQs on TMT Bar Price in India

Q1. Why does the price change almost every day?

Because raw material, fuel, and demand change often. Dealers follow the mill circulars and local conditions.

Q2. Is the lowest price always bad?

Not always. But if the price is much lower than the general market, check size, weight, and documents carefully.

Q3. How can I know if I am getting a full-size?

Measure the diameter with a vernier. Weigh a fixed length and compare with standard tables.

Q4. Should I buy all steel in one shot?

For a small house, buying most of your requirements in one or two lots usually helps. For very long projects, a phased plan may be better.

Conclusion

In India today, the TMT Bar Price is shaped by many factors. Raw material cost, plant technology, grade and ductility, transport, and market demand all play a role. For a smart buyer, the key is not to chase the absolute lowest number. The key is to get honest size, reliable quality, and timely supply at a fair price.

Choose a TMT Steel Bar from a trusted brand. Ask for the grade, documents, and actual size. Plan purchases with your engineer and dealer. Kamdhenu is one of the options that tries to balance quality and cost for Indian building conditions. When you understand the price logic and make calm, informed choices, your structure gets the strength it needs, and your budget stays under control.