January 28 2026

January 28 2026

MS Pipes Buying Guide: Choose the Right Steel Pipe Types Before You Place the Order

MS Pipes Look Simple. But Buying the Wrong Pipe Is Expensive.

MS pipes look simple. But buying the wrong pipe is expensive.

It slows fabrication. It increases wastage. It weakens joints. It creates site rejection.

That is why buyers now ask one basic question first. Which steel pipe types fit my application?

This guide is built for contractors, fabricators, engineers, distributors, and project owners. It is practical. It is specification-led. And it is written for transactional intent. So you can shortlist fast. And purchase with confidence.

We will cover three essentials: MS pipes, hollow section pipes, and how to match them to use cases.

Why MS Pipes Are a High-Impact Purchase

Steel demand keeps growing in India. The country is also one of the world’s largest crude steel producers. That growth increases choices in the market. It also increases confusion. On ground, most pipe problems come from basics.

- Wrong thickness

- Wrong section

- Poor dimensional accuracy

- Weak documentation

- Damage in transit

So you need a clean selection method.

The 3 Most Used Steel Pipe Types in Construction and Fabrication

Think in sections. Not in generic “pipe.”

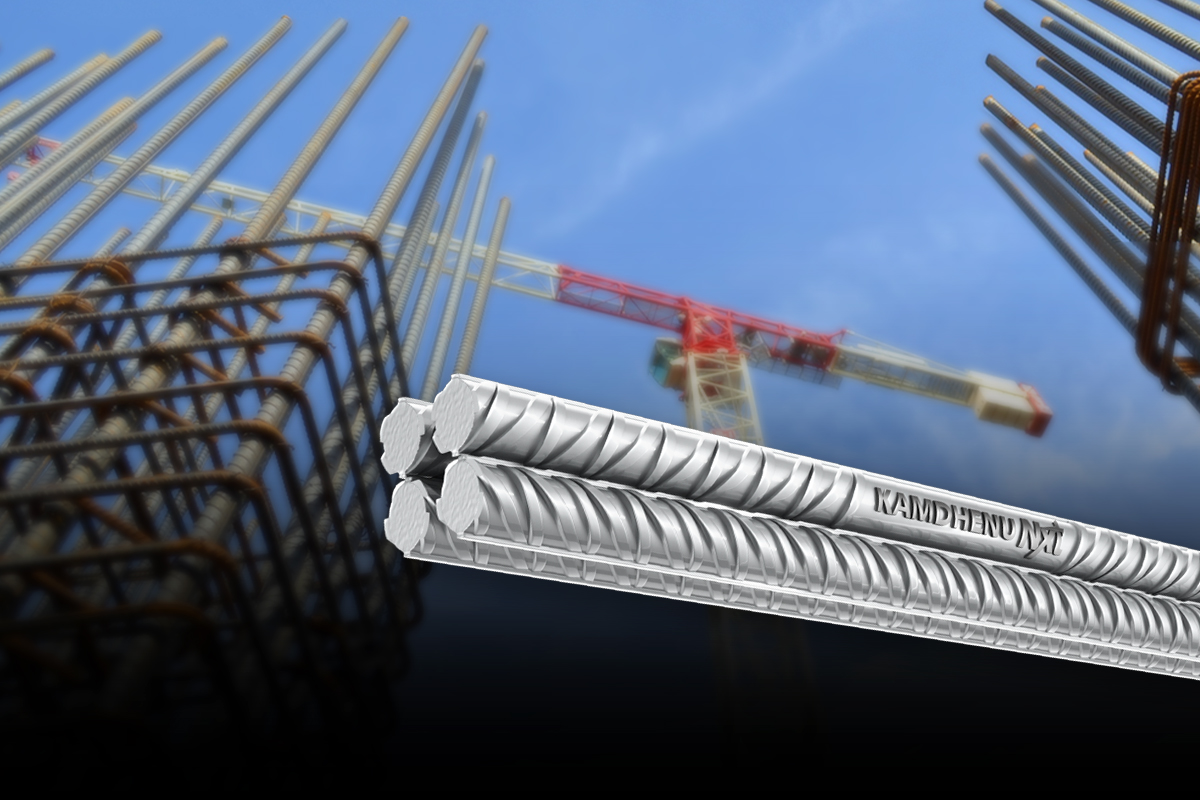

1) Circular Hollow Sections (CHS)

CHS is round. It is used where stiffness and uniform load distribution matter. Common in columns, struts, and general frameworks.

Kamdhenu Pipes CHS are offered with bore variants from 15 mm to 100 mm. And with wall thickness classifications of Light, Medium, and Heavy.

This classification approach also aligns with how IS 1239 groups steel tubes.

2) Square Hollow Sections (SHS)

SHS is square. It is preferred when alignment matters. And when clean corners improve aesthetics. Common in railings, fencing, gates, and architectural frames.

3) Rectangular Hollow Sections (RHS)

RHS is rectangular.

It is a workhorse for frames.

It gives higher stiffness in one direction.

It is widely used in sheds, supports, and fabrication lines.

RHS is also chosen for welded steel frames that take loading in multiple directions. Its flat surfaces make fabrication easier.

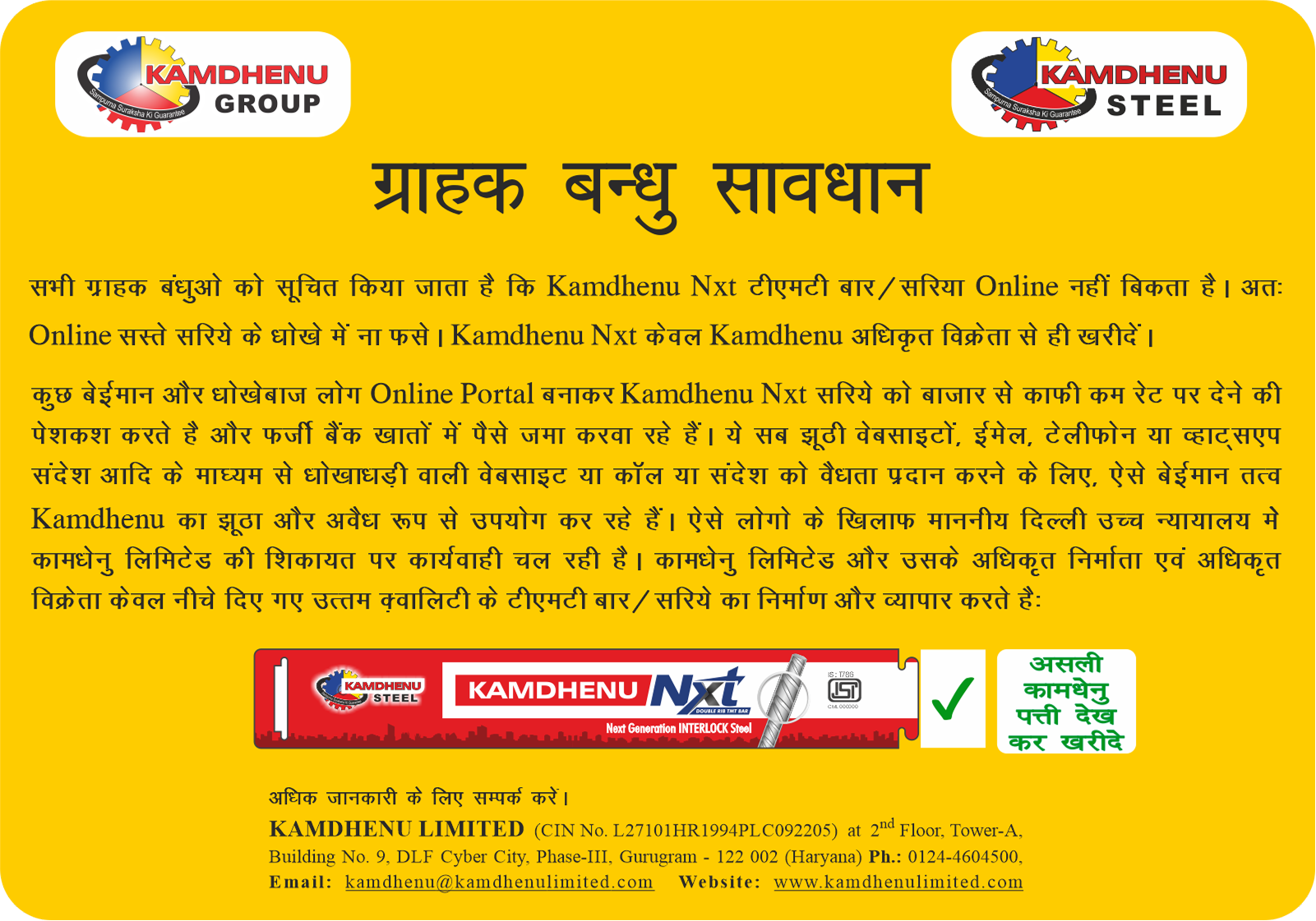

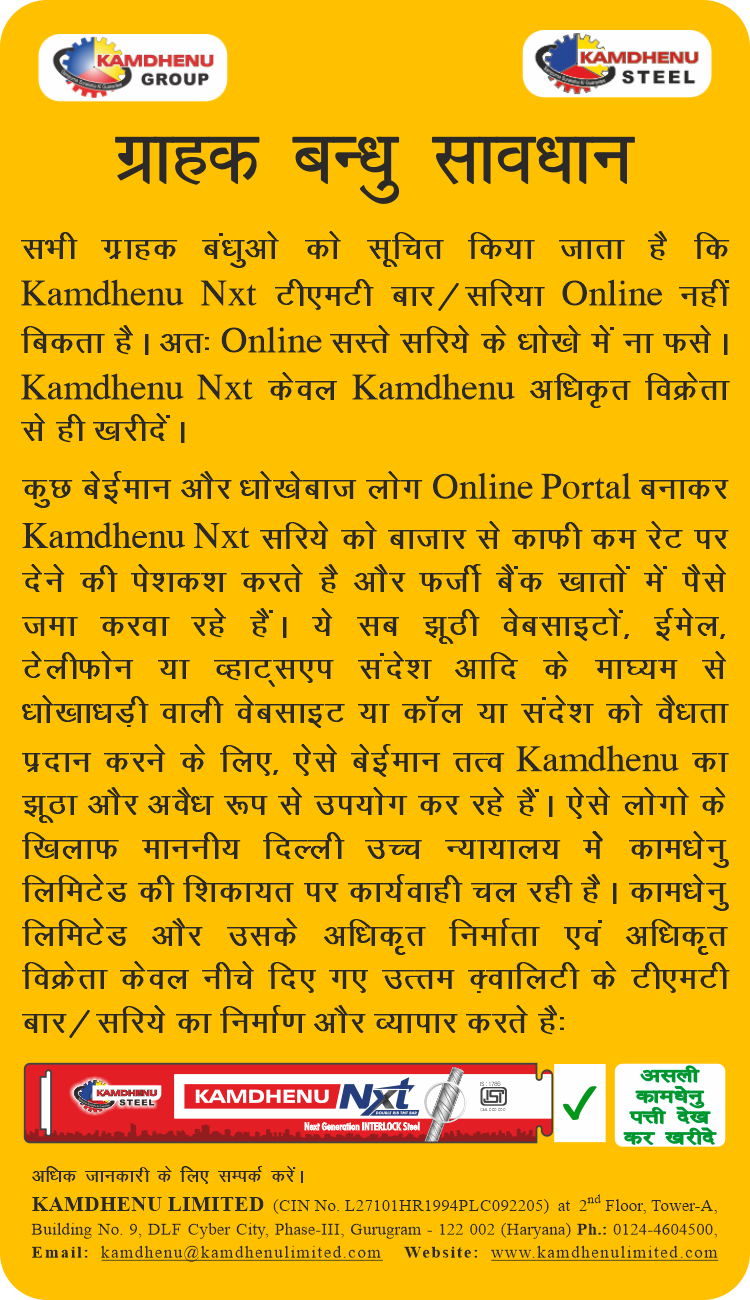

Standards That Matter (And Why “As Per” Is Not Enough)

If the application is structural, don’t stay vague. Ask which standard the supplier is aligning to.

IS 1239 (Part 1) covers welded/seamless steel tubes intended for water, non-hazardous gas, air, and steam.

IS 4923 specifies hollow steel sections for structural use, including marking requirements on sections.

This is not paperwork. It is your quality baseline.

Match Use Case to Pipe Type

| Where you will use it | Preferred section | What to specify on the PO |

|---|---|---|

| Building framework members | CHS / RHS | Size, thickness class, length, standard |

| Railings, gates, fencing | SHS | Section size, thickness, finish, length |

| Industrial frames and supports | RHS | Section size, stiffness need, tolerance expectations |

| General fabrication | CHS / SHS | Dimensional accuracy, weld seam quality, straightness |

The MS Pipes Procurement Checklist (Use This Before Payment)

- Confirm section type - CHS, SHS, or RHS.

- Confirm size range and acceptable tolerances.

- Confirm thickness and class where relevant.

- Confirm length. Standard or cut-to-length.

- Kamdhenu Pipes are supplied in standard lengths or as per customer requirements.

- Confirm application. Structural or utility.

- Ask how batches are tested.

- Tensile strength and dimensional accuracy checks are a good baseline.

- Ask about packaging. Bundling and documentation reduce transit damage and disputes.

- Inspect sample pieces. Check straightness and corner sharpness.

- Ask for the documentation format. Invoice clarity matters.

- Buy from a dealer with steady stock. Consistency reduces mid-project substitutions.

Corrosion Is a Cost. Not a Cosmetic Issue.

If your MS pipes are exposed, plan protection. Especially in coastal zones or industrial zones.

Corrosion is not a small problem globally.

The AMPP/NACE IMPACT study estimates the global cost of corrosion at US$2.5 trillion, about 3.4% of global GDP (2013).

That number is not “just theory.” It shows why surface condition and protection decisions matter. Even for standard MS pipes.

What to Expect From a Serious Structural Tube Range

When you buy structural tubes, you want predictable performance.

And predictable fabrication.

Kamdhenu Pipes are positioned as MS pipes and tubes for diverse construction needs.

They are offered in Circular, Square, and Rectangular Hollow Sections.

- Focus on dimensional accuracy.

- Ease of fabrication from uniformity.

- Strong support for structural applications.

- Rigorous quality checks, including tensile strength and dimensional accuracy testing.

- Packaging and dispatch with documentation.

For buyers who want range coverage, the structural tubes brochure also notes:

Kamdhenu Nxt hollow structural sections offer over 60 product variants.

That matters when your project has mixed sizes.

It reduces supplier switching.

Read More: The Rise of Rectangular Hollow Sections in Indian Construction

A Practical Trust Signal: Supply Network and Availability

Transactional buyers care about one thing.

Can the material arrive on time?

Kamdhenu’s structural products brochure states:

- Brand turnover of more than ₹16,000 crores.

- More than 80 franchisee manufacturing units.

- 11,500 dealers and distributors across India.

For procurement teams, that signals reach.

And repeat availability.

What You Should Do Next

- Compare your requirement to the CHS / SHS / RHS selection above.

- Prepare a short RFQ.

- Include section, size, thickness, and length.

- Compare specifications.

- Not only price.

- Download the Kamdhenu Pipes brochure from the product page.

- Contact your nearest dealer for stock and dispatch timeline.

MS pipes are not a commodity when deadlines are tight.

Choose the right steel pipe types. Specify clearly. And buy with documentation.

That is how you reduce risk.

And build faster with fewer surprises.